Highlights

Core strengths of Adobe PDF Print Engine

Advanced color capabilities

State-of-the-art color management and powerful color controls. Manage process and special inks. Maximize gamut and visual impact by accounting for substrates and inks.

Performant and robust architecture

Engineered for speed, scalability, and reliability. Take full advantage of available system resources to render complex graphics and jobs at record speed.

Industry-leading print quality

Proprietary processing technologies for superior reproduction of every element type: text, graphics, images, and smooth shades, either stand-alone or in combination.

Dynamic workflow capabilities

Flexibility to support specialised job and device requirements. Functionality to address a broad range of job types and production environment workflows.

Power to customise

Customisable integration points for adding proprietary value. Differentiate solutions to build products that stand out.

Reliability = Predictability + Consistency

Adobe end-to-end workflow

Customers who build their print jobs with Adobe applications such as Photoshop, Illustrator, InDesign and Express benefit from consistent technology across the end-to-end job lifecycle. Using the same Adobe technology to create, manage and print results in reliable reproduction. Adobe PDF Print Engine also excels at rendering jobs created in non-Adobe applications.

Advanced colour capabilities

Colour management: built-in or proprietary

- PDF Print Engine includes the Adobe Color Engine for state-of-the-art colour conversion.

- Adobe Creative Cloud applications and Acrobat use the same CMM (Colour Management Module).

- Alternatively, systems have the option to integrate a 3rd-party CMM with PDF Print Engine.

Sophisticated controls for managing colour conversions

- Content and context-aware colour management:

- Options to customise colour for target press/proofer.

- Controls to emulate press conditions on a proofing device.

- Colour operations based on object type. (e.g., text, vectors, images).

- Intelligent controls based on device capabilities and job content.

- Ability to customise colour conversions using tags by passing private data via profiles to custom CMM.

- Source colour replacement.

- Black Point Compensation (BPC).

- Spot colour replacement (at source or emulation at output).

- Device Colour Adjustment interface.

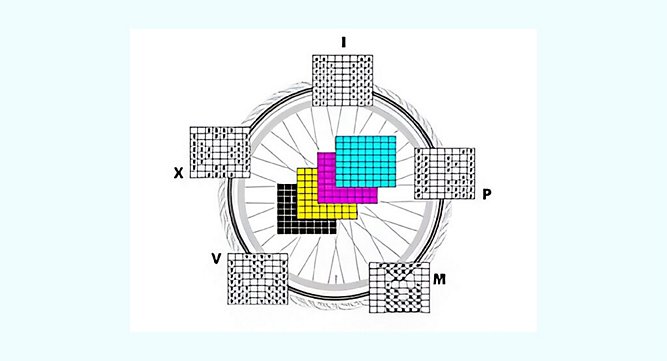

Streamlined processing for Expanded Colour Gamut (ECG) presses

- Utilise the full available colour gamut on the press by generating multiple plates/planes beyond CMYK.

- For example: on presses with CMYK ink stations plus Orange/Green/Violet (CMYK-OGV).

Auto-generate plates for white underlay and varnish

- White underlay: When printing on fabric, direct-to-film (DTF), clear plastic or various packaging substrates, a white plate can be automatically derived in-RIP from the design elements and printed first to make the design colours more vibrant.

- Varnish overlay: When a clear varnish can be overprinted, it can be automatically generated in-RIP from page contents, to highlight design elements and increase visual impact.

- Controls:

- Alpha channel mask - to enable transparency interactions with coloured substrates.

- Choke and spread - edges can be controlled and extended.

Corporate brand colours using spectral values

- When brand colours are precisely defined by spectral values (e.g., CxF data), PDF Print Engine can seamlessly transform these colours into CIELAB values considering ambient conditions.

- Enables spectral brand colours to be colour-managed using the same method as the other colours in the job.

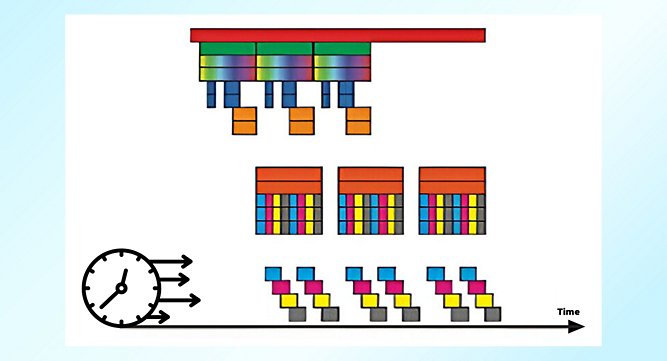

Performant and robust architecture

- Scalability platform for dynamically managing multiple PDF Print Engine instances, working in tandem on multicore or blade systems.

- Mercury RIP Architecture enables high-speed rendering of job content, including VDP, of any complexity to drive a high-volume or multiple presses at their rated speeds.

- Local, shared local, shared global cache hierarchy across multiple instances.

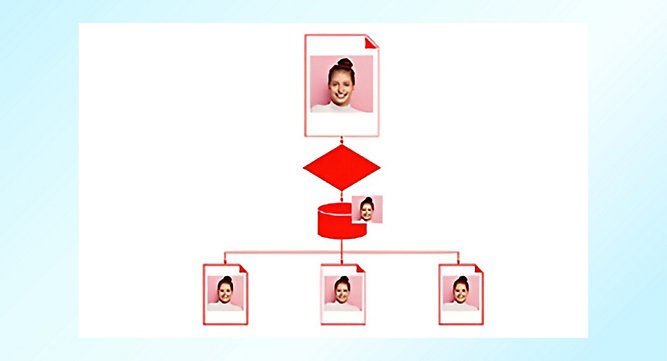

Variable printing: cache and retrieve common elements

- Recurring elements are cached and retrieved to eliminate redundant processing.

- Multi-level caching support for:

- Repeating patterns.

- Object-level caching with cutting-edge technology for opaque and transparent objects.

- Nested objects.

- Entire PDF pages for step-and-repeat workflows.

Context and content-aware transparency decision engine

- Automated selection of optimal transparency blending algorithm that balances performance and visual quality.

- Employs job intelligence for context and content-aware decisions.

Parallel processing at every stage in the pipeline

- Optimise resource usage via multi-threading for both single-core and multi-core systems.

- Optimised for enhanced CPU instruction set.

Optimised processing of PDF files generated at run-time

- Begin rendering of long transactional print jobs before they are completely generated.

Handle non-compliant PDFs

- PDF Print Engine can provide multiple control points to handle non-compliant PDFs.

Robust and intelligent memory management

- System-wide, co-ordinated memory management along the entire processing pipeline to reduce peak memory requirements and avoid job failures caused by memory constraints.

Industry-leading print quality

Adobe live transparency blending

- Full support for all blend modes and blending colour spaces as defined in the latest PDF specifications.

- Appearance-based mixing for non-available spot colours.

Future-ready image processing

- Sophisticated image scaling utilising proprietary Photoshop algorithms.

- Edge-to-edge image printing for textile designs.

- Handling 16-bit images that have non-standard channels.

Proprietary font rendering

- High-quality font rendering that leverages the Adobe-proprietary font engine.

Fine line rendering

- Optional enhanced processing of elements with very thin lines or fills, such as barcodes, security lines or outlined text in small point size.

- A light touch prevents ink from spreading and produces a clean, crisp appearance.

Seamless smooth gradients

- Seamless gradients and smooth shades, using higher precision rendering pipeline.

- Gradient transitions are designed to avoid abrupt changes or band artefacts.

Accelerated anti-aliasing of text and vectors

- Visually smooth jagged edges of text and graphics.

- High-speed anti-aliasing that balances bit depth, resolution and device controls (e.g., take advantage of multiple droplet sizes).

In-RIP trapping

- Efficient choking and spreading at edges of adjacent objects.

- Rules can be applied to text, graphics and image interactions.

- Available as an optional booster package.

Dynamic workflow capabilities

Comprehensive PDF/VT support

- PDF Print Engine supports the latest PDF/VT (ISO 16612) workflows for Direct Mail, Customer Correspondence, Transactional, Transpromo and Variable Product Printing (VPP).

- Offers sophisticated handling of non-printing metadata, giving you complete control through JDF.

Native consumption of images and external objects

- Extensible direct image consumption.

- Sophisticated handling of externally referenced placed objects (Xobjects, PDF pages).

Integration with post-press finishing

- Interface to pass cut-path vectors to post-press finishing equipment.

- Generate a separate plate for the cut contours.

- Global transformations applied to job content (e.g., scale, rotate, shift) will also be applied to the cut contours.

- In compliance with PDF Processing Steps international standard (ISO 19593).

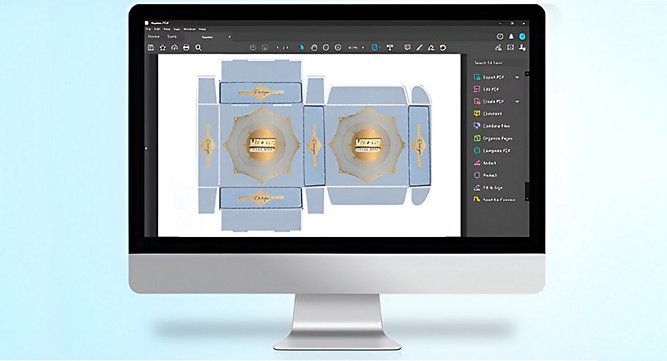

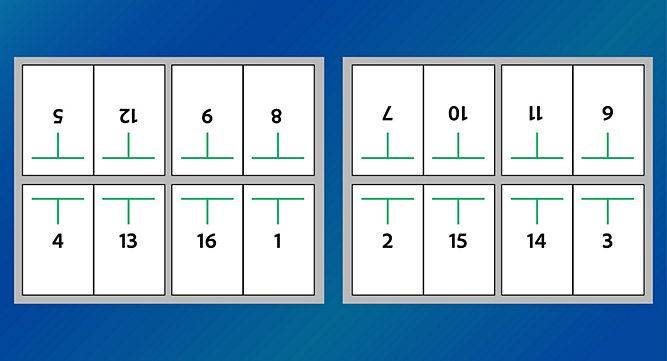

In-RIP imposition (automated and non-automated)

- Leverage automated capabilities of JDF job ticket format to impose pages into signatures for cut-and-stack, saddle stitch and other imposition schemes.

- Rule-based insertion of pages/sheets.

- Conforms to CIP4 Imposition ICS (Interoperability Conformance Specification).

Content-aware smart pixel metadata

- PDF Print Engine augments ink-channel values with five metadata categories for each pixel. The metadata conveys information about the origin of each graphic, which can be harnessed to enhance colour management, optimise compression, caching and other purposes.

Extensive support for a full range of device configurations

- Support for all device configurations: frame, band or tile. It also supports various bit depths, resolutions and multiple rendering modes.

- Support for presses with different bit-depths (1/2/3/4/8/16) & resolution types (isotropic and anisotropic).

- The full surface can be imaged in a single operation or the surface can be subdivided into bands and/or tiles for greater efficiency.

- Multiple rendering modes enable rendering the same page with different parameters. For instance, a preview rendition can be followed by a full rendition with different resolutions, media sizes, clip paths and transforms.

Power to customise

Enable run-time attribute discovery and modification of PDF job files

- Default read-only helper module, plus optional integration with Adobe PDF Library SDK.

Enable run-time image enhancement

- Interface to integrate proprietary image operations into the RIP. For example, resampling, image modification, colour correction and image replacement.

Complete control over the marking module

- Full-featured, powerful marking module that can be used out-of-the-box or replaced to target specialised needs.

OEM-proprietary colour management support

- Harness OS-provided CMM or proprietary CMM for managed colour conversions to address OEM customised colour management needs.

- Implement independent late-stage adjustment (post-CMM) of device colour planes. E.g., ink limiting or proprietary spot blending.

OEM-proprietary file system

- Optional support for OEM supplied file-system for maximum security. Access files from any file systems (OS, RAM disc, cloud).

Customisable control over VDP caching

- What to cache and when

- Rendered form of raster cached objects (e.g., proprietary)

- Where to cache (RAM disc, shared memory, other location)

- Type of caching (object vs. page)

- In-RIP caching as a display list or OEM-customisable raster cache

Advanced JDF configuration support

- Partition job to enable page/surface/document-level configuration controls (e.g., treating cover, body, pages differently).

Versatile job submission methods

- Support for hot folders, MIME-packed PDF/VT-2s and JMF job submission modes (Job Messaging Format).

- URLs for job resources (e.g., ICC profiles, PDF files, half-tone screens, calibration curves) can be local or remote HTTP.